Subject matter experts from Regulatory Compliance Associates® Inc. discuss how too many organizations scramble when an FDA inspection occurs because they fail to be adequately prepared. True inspection preparedness, however, supplements internal audits with a practiced inspection process and focused behavioral training.

Internal Audit

While internal audits are a key component of inspection preparedness, they tend to be informal, less intense, and more focused on auditing than inspecting. True inspection preparedness supplements internal audits with a practiced inspection process and focused behavioral training for key personnel.

Before a FDA inspection occurs, organizations should have an inspection process in place and conduct mock inspections. Like any process, inspection readiness needs a plan that is executed, assessed, and continuously improved upon.

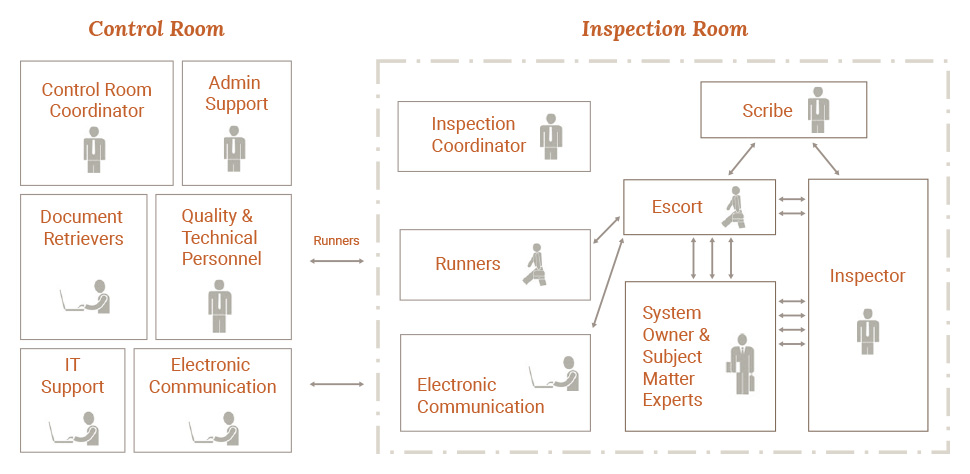

Roles & Responsibilities

The Inspection Room (Front Room)

While inspectors often walk the facility, the inspection room provides a meeting space to review documentation and answer questions from the inspectors. In this “front room,” system owners or subject matter experts (SMEs) review and present materials to the FDA inspector.

The Control Room (Back Room)

The control room provides the documentation, interviewees, and preparation that is needed to support the inspection process. This “back room” team processes requests for information, retrieves documents from electronic systems, and also triages documents as needed. The control room is staffed with quality and technical personnel who log requests for information and alert department heads within the organization.

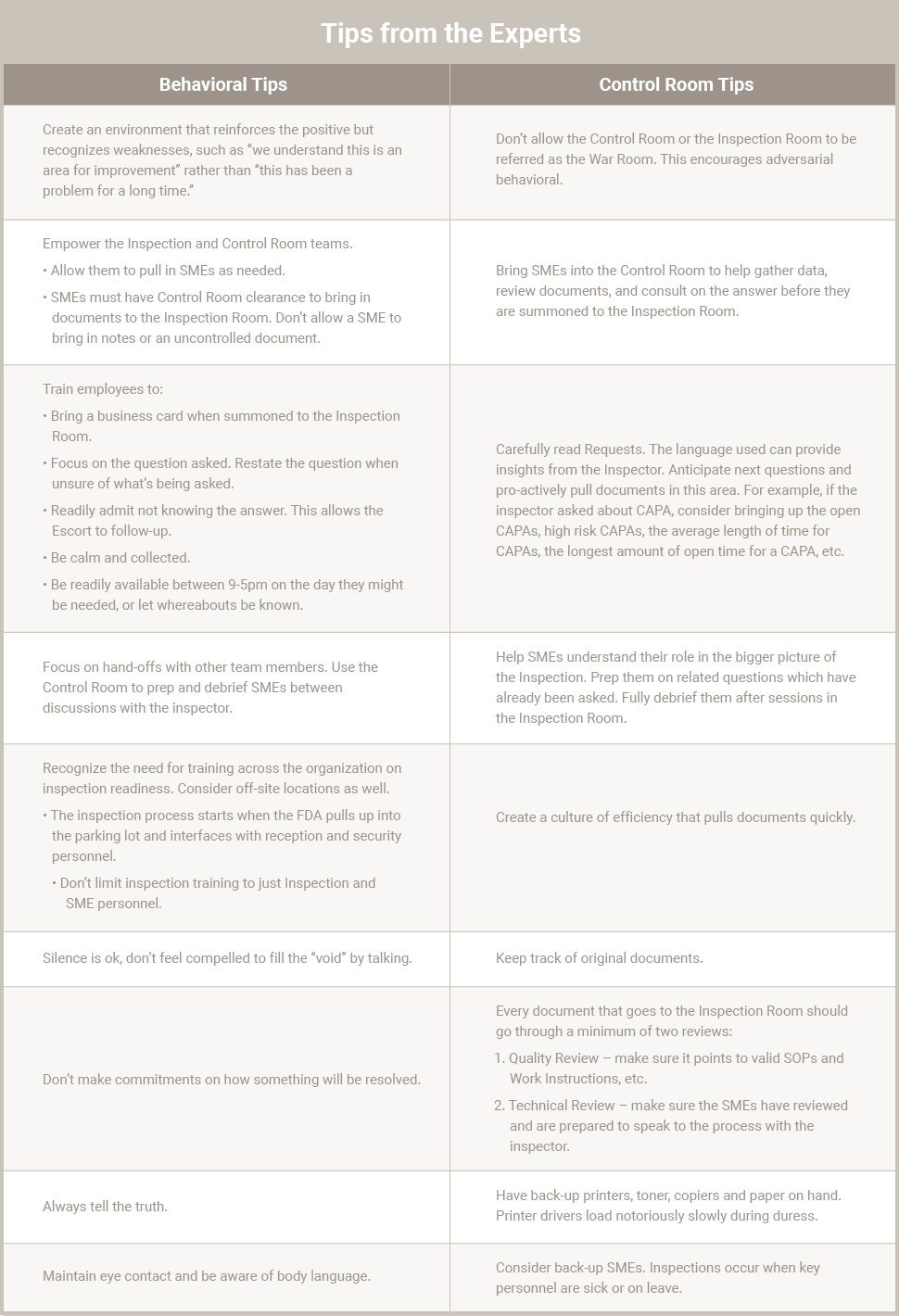

Control room personnel should always:

- Conduct a minimum of two reviews of every document prior to sending it to the inspection room:

- Quality Review:

- Make sure it points to valid SOPs and Work Instructions, etc.

- Technical Review:

- Make sure the SMEs have reviewed and are prepared to speak to the process with the inspector

- Have back-up printers, toner, copiers and paper on hand

Some organizations appoint runners to take the data back and forth between the control room and inspection room. There are technology solutions to operationalize the inspection process as well.

Behavioral Training

In the past, employees were often trained to give curt answers to FDA inspectors to avoid inadvertent revelations to the agency. This approach created fear and mistrust among employees, and set up adversarial relationships with FDA staff. In order to create the most beneficial inspection process environment, however, both the agency and the company need to form a partnership. Key behavioral tips for success include:

- Empower the inspection and control room teams.

- Bring SMEs into the control room to help gather data, review documents, and consult on the answer before they are summoned to the inspection room.

- Help SMEs understand their role in the bigger picture of the inspection. Prep them on related questions that have already been asked.

- Don’t allow an SME to bring in notes or an uncontrolled document.

- Use the control room to debrief SMEs after meetings with the inspector.

- Anticipate and prepare. The language used in inspector requests can provide insights. Anticipate next questions, proactively pull documents, and understand related metrics. For example, if the inspector asks about CAPA, review related documents such as open CAPAs, high-risk CAPAs, the average length of time for CAPAs, and the longest time for open CAPAs. Be prepared to answer the inspector’s next questions.

Practicing the inspection process, however, can be one of the best ways to help employees learn appropriate behaviors and response techniques. Train employees to:

- Focus on the question asked; restate the question when unsure of what’s being asked.

- Readily admit to not knowing an answer, but provide a date and time when the answer will be provided.

- Create an environment that reinforces the positive but recognizes weaknesses, such as “we understand this is an area for improvement,” rather than “this has been a problem for a long time.”

- Recognize the need for training across the organization on inspection readiness. Consider off-site locations as well. The FDA inspection process starts when the FDA inspector pulls up into the parking lot and interfaces with reception and security personnel. Don’t limit inspection training to just inspection and SME personnel.

Mock Inspections

Many companies conduct internal audits as part of their inspection readiness strategies. Mock inspections, however, take the next step and allow companies to actually practice the inspection room, the control room, and inspector interaction.

During mock inspections, organizations set up inspection rooms and control rooms to help teams learn how to readily access documentation that would potentially be requested during an inspection. Additionally, these practice sessions give employees an opportunity to demonstrate proper behavior and interviewing techniques when working with the regulatory agency.

A mock inspection can also be used to probe further on issues uncovered during internal audits. The mock Inspection team should bring in SMEs and other personnel as needed for this activity. This approach helps the organization fully understand areas needing improvement, and gives them a platform to take corrective action before the agency actually arrives.

Being properly prepared for inspection ensures that the inspection process will run smoother, decreases the likelihood of observations, and helps groom the organization and individuals for higher levels of future performance.

Published by:

Medical Device and Diagnostic Industry.

About RCA’s Pharmaceutical Consulting Services

Regulatory Compliance Associates (RCA) has helped thousands of pharmaceutical companies meet regulatory, compliance, quality assurance, and remediation challenges. With more than 20 years of experience with FDA, Health Canada, EU and global regulatory agencies worldwide, Regulatory Compliance Associates® offers leading pharmaceutical consultants. We’re one of the few pharma consulting companies that can help you navigate the challenges associated with industry regulations.

Our pharmaceutical consulting firm includes over 500 seasoned FDA, Health Canada & EU compliance consultants and regulatory affairs experts who understand industry complexities. It’s a pharma consultancy founded by regulatory compliance executives from the pharmaceutical industry. Every pharmaceutical industry consultant on the Regulatory Compliance Associates team knows the unique inner workings of the regulatory process.

Client Solutions

Whether you’re in the product planning, development or pharmaceutical lifecycle management stage or need a remediation strategy for a compliance crisis, Regulatory Compliance Associates will guide you through every pharmaceutical consulting step of the regulatory process and create a customized approach depending on your product and your pharma company’s individual needs. Our regulatory compliance clients include:

- Companies new to FDA, Health Canada or EU regulations and regulatory compliance

- Start-up organizations with novel submissions to 510(k) submissions from multi-national corporations

- Investment firms seeking private equity due diligence for pre-acquisition and post-deal research

- Law firms seeking pharmaceutical consulting firm expertise in the remediation of warning letters, consent decrees, 483’s or import bans

Regulatory Affairs

Regulatory affairs is Regulatory Compliance Associates backbone. We exceed other pharma consulting companies with industry experts experienced in complexities of the pharmaceutical and biopharmaceutical industries. Our pharma consulting expertise spans all facets and levels of Regulatory Affairs, from Regulatory Support for New Products to Life Cycle Management, to other services like Outsourced Regulatory Affairs, Submissions, Training, and more.

As your partner, we can negotiate the potential assessment minefield of regulatory compliance services with insight, hindsight, and the clear advantage of our breadth and depth of knowledge and regulatory compliance consulting. We offer the following pharma consulting regulatory affairs services for pharmaceutical companies.

- New Product Support

- Product Lifecycle

- Other Regulatory Services

- Combination Products

Compliance Assurance

The regulations process surrounding pharmaceutical companies can be tricky for even the most experienced industry veteran to understand. Just one misstep could mean significant and lasting consequences for your business. At Regulatory Compliance Associates, we offer the pharma consulting experience and pharma consultants necessary to guide you through the quality compliance process.

- Assessments

- Audits

- Regulatory Agency Response

- Preparation and Training

- Inspection Readiness

- Data Integrity

Quality Assurance

Regulatory Compliance Associates Quality consulting includes assessments, strategy, implementations, staff augmentations, and identification of quality metrics to ensure continuous improvement. Our pharma consultants understand the strategic thinking needed to align your business needs and goals. Regulatory Compliance Associates quality assurance services include quality experts with experience spanning major corporations and start-ups. Our pharmaceutical consulting firm knows firsthand how to achieve, maintain, and improve quality, and we excel in transferring pharma consulting knowledge to your organization.

- 21 CFR Part 11

- Data Integrity

- Manufacturing Support

- Facility Support

- Quality Metrics

Remediation Services

Regulatory Compliance Associates has a proven remediation services approach to managing FDA Warning Letters, Consent Decrees, Remediation and other serious regulatory situations. Our pharma consultants know how to partner with executive, legal, and communication teams. Each RCA pharma consulting Expert will develop a response that will be accepted by the regulatory agency and be realistic to execute.

Regulatory Compliance Associates pharma regulatory consultants will develop a comprehensive proof book of documented evidence demonstrating the corrective action taken to remediate non-compliant issues. In addition, each Regulatory Compliance Associates pharma consulting Expert understands compliance enforcement. We’ll prepare a comprehensive pharma consulting strategy to assist in your remediation efforts, drive continuous improvement, and maintain regulatory compliance with the regulations.

- Regulatory Action

- Regulatory Compliance

- Regulatory Enforcement

- Warning Letter

- 483 Observation

- Oversight Services

- Risk Management Plan

About Regulatory Compliance Associates

Regulatory Compliance Associates® (RCA) provides pharmaceutical consulting to the following industries for resolution of life science challenges:

Regulatory Compliance Associates® (RCA) provides pharmaceutical consulting to the following industries for resolution of life science challenges:

- Life Sciences

- Pharmaceutical

- Biologic & Biotechnology

- Sterile compounding

- Medical device

- Lab Testing

We understand the complexities of running a life science business and possess areas of expertise that include every facet of R&D, operations, regulatory affairs, quality, and manufacturing. We are used to working on the front lines and thriving in the scrutiny of FDA, Health Canada, MHRA and globally-regulated companies.

As your partners, we can negotiate the potential minefield of regulatory compliance and regulatory due diligence with insight, hindsight, and the clear advantage of our unique expertise and experience.

- Founded in 2000

- Headquartered in Wisconsin (USA)

- Expertise backed by over 500 industry subject matter experts

- Acquired by Sotera Health in 2021

About Sotera Health

The name Sotera Health was inspired by Soteria, the Greek goddess of safety, and reflects the Company’s unwavering commitment to its mission, Safeguarding Global Health®.

Sotera Health Company, along with its three best-in-class businesses – Sterigenics®, Nordion® and Nelson Labs®, is a leading global provider of mission-critical end-to-end sterilization solutions and lab testing and advisory services for the healthcare industry. With a combined tenure across our businesses of nearly 200 years and our industry-recognized scientific and technological expertise, we help to ensure the safety of over 190 million patients and healthcare practitioners around the world every year.

We are a trusted partner to 5,800+ customers in over 50 countries, including 40 of the top 50 medical device companies and 9 of the top 10 pharmaceutical companies.

Commitment to Quality

Our Certificate of Registration demonstrates that our Quality Management System meets the requirements of ISO 9001:2015, an internationally recognized standard of quality.

To begin the Regulatory Compliance Associates scoping process today, please enter your information in the blue form below and click the submit button at the bottom of the webpage.