Published Articles

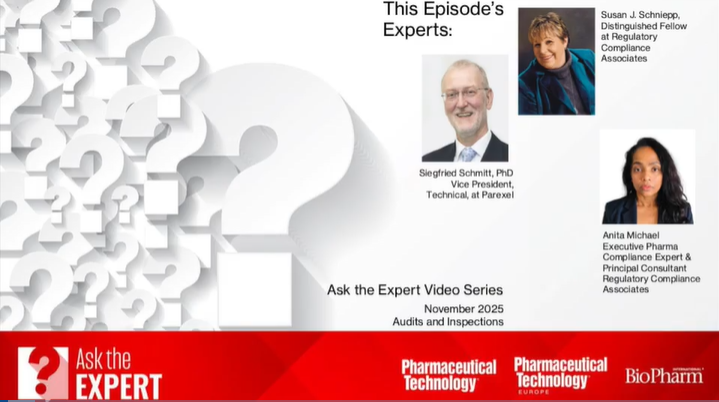

In this episode of the Ask the Expert video series hosted by Pharmaceutical Technology®, Susan J. Schniepp, Regulatory Compliance Associates (RCA), Siegfried Schmitt, Parexel, and Anita Michaels, RCA, explain how CDMOs can best handle regulatory inspections and client expectations.

Link to the Video and Article on Pharmaceutical Technology

Contract development and manufacturing organizations (CDMOs) typically have multiple clients who each have specific needs. When regulators perform audits and inspections of CDMOs, it is sometimes unclear who is responsible for any deviations the inspector might have. However, ultimately, the sponsor company is responsible for ensuring that any contract organizations are following good manufacturing practices.

But what happens when a CDMO has a client that has specification and/or requirements that infringe on that contractor’s ability to work with other clients? How should the CDMO respond to audits and their clients? In this episode of Ask the Expert, Susan J. Schniepp, distinguished fellow at Regulatory Compliance Associates, a Nelson Labs company (RCA); Siegfried Schmitt, vice president Technical at Parexel, and Anita Michaels, executive pharma compliance expert and principal consultant at RCA, give advice on how contractors and clients can work together to prepare for inspections and address regulatory actions.

“A lot of CDMOs utilize their clients’ inspections to prepare for inspection. But I think you could level up, level that up higher,” Michaels says. “The first thing is you want to have a robust quality system. And you also want to integrate the other five systems into your facility. Then you’ll receive, if it’s a regulatory authority like the FDA, they could come to inspect you for a GMP or pre-approval inspection, which will be specific to the product they’re covering. And then the GMP portion, if you have been approved for a United States product, would cover the six systems. So, I think holistically, a CDMO should prepare, number one, to handle a GMP covering the six systems and have a robust quality system, such as policies in place for your CAPAs [corrective and preventative actions], investigations, deviations, your KPIs, your tracking, and trending holistically across your facility. And then also understanding the approach for a preapproval inspection for your clients.”

Click the video above to watch Sue, Siegfried, and Anita answer the following question:

“How does a CDMO organization handle multiple client input and perspective with regard to general GMP inspections without compromising or setting up different standards within their Quality Management System?

Strengthen your inspection readiness with a partner who understands the full regulatory landscape.

RCA supports pharmaceutical and medical device organizations with comprehensive audit preparation, supplier oversight, CDMO qualification, remediation planning, and ongoing quality system optimization. Whether you’re scaling operations or navigating complex regulatory expectations, our experts help you reduce risk and ensure confidence in every inspection.

Take the next step toward true compliance readiness.

Explore our full range of services here: Compliance Assurance Services

Or connect with our team to discuss your tailored compliance strategy today.

Connect with RCA Today

Contact us to learn more about our regulatory compliance experts and how they can help